The Ultimate Guide to Automatic Joint Roller Machines

An automatic joint roller machine is pretty much what it sounds like: a device that takes the guesswork and manual labor out of making prerolls. It offers a level of speed, consistency, and precision that you just can't get by hand. Forget the slow, often inconsistent art of hand-rolling; these machines are now essential tools for turning out perfectly uniform joints every single time. For both serious smokers and commercial brands, they're a total game changer.

Why Automatic Rollers Are a Game Changer

There's a certain charm to the traditional art of rolling a joint. It’s a hands-on ritual that many people love. But let's be honest—it takes a lot of practice to get right. More often than not, you end up with joints that burn unevenly, draw poorly, or just fall apart halfway through. It's frustrating, especially when you're working with premium THCA flower and want every puff to be perfect.

For commercial brands, those hand-rolling challenges are magnified a thousand times over. Relying on people to roll is slow, costs a ton in labor, and brings human error into the mix, which hurts product quality. Churning out thousands of prerolls that all look and smoke the exact same way is nearly impossible by hand. This is where an automatic joint roller machine completely changes the game, turning a manual craft into a precise, repeatable science.

The Leap from Hand-Rolling to Automation

Think of it like the difference between hand-stitching a shirt and using a modern sewing machine. Both get the job done, but the machine delivers flawless, identical results in a fraction of the time and for far less money. Automation completely removes the guesswork and dexterity needed for a perfect roll.

These machines handle every critical step with mechanical precision. They make sure the flower is packed with the ideal density—not so tight that you can't get a draw, and not so loose that it burns up in seconds. The result is a consistently smooth smoke and an even burn from start to finish. The benefits are obvious right away:

- Unmatched Consistency: Every single preroll is a perfect clone of the last. Your customers get the same high-quality experience with every purchase.

- Superior Speed: A single machine can crank out hundreds or even thousands of joints an hour. You'd need a whole team of people to even come close to that.

- Reduced Waste: Precise filling mechanisms mean less spilled flower, which saves money and makes sure all your valuable material ends up in the joint.

Preserving Terpenes and Potency

Beyond just making things faster and more uniform, an automatic joint roller machine is also crucial for preserving the quality of the cannabis itself. Premium THCA flower is loaded with delicate terpenes, which are the aromatic compounds that give a strain its unique flavor and effects.

The gentle, controlled handling from a machine avoids the heavy pressure and friction of hand-rolling, which can easily crush the delicate trichomes and degrade those volatile compounds. By protecting the flower's integrity, these machines make sure the final product delivers the full-spectrum experience the grower intended.

At the end of the day, this technology is more than just a convenience—it's a critical tool for quality control. It gives both connoisseurs and commercial producers the power to deliver a reliable, top-tier product that meets the high standards of today's cannabis market. You get a perfect preroll, every single time.

How an Automatic Joint Roller Machine Really Works

Forget thinking of an automatic joint roller as a simple gadget. It’s more like a miniature, high-precision assembly line, designed to turn loose flower into perfect pre-rolls every single time. Where hand-rolling is an art form full of variables, these machines follow a repeatable, multi-stage process engineered for flawless consistency.

The whole operation is built on controlled movements and exact measurements. It takes the trickiest parts of rolling—getting the density right, keeping the shape uniform, and sealing it all up without a tear—and automates them. Each step is designed to be gentle on the flower, protecting the delicate trichomes that hold all the flavor and potency.

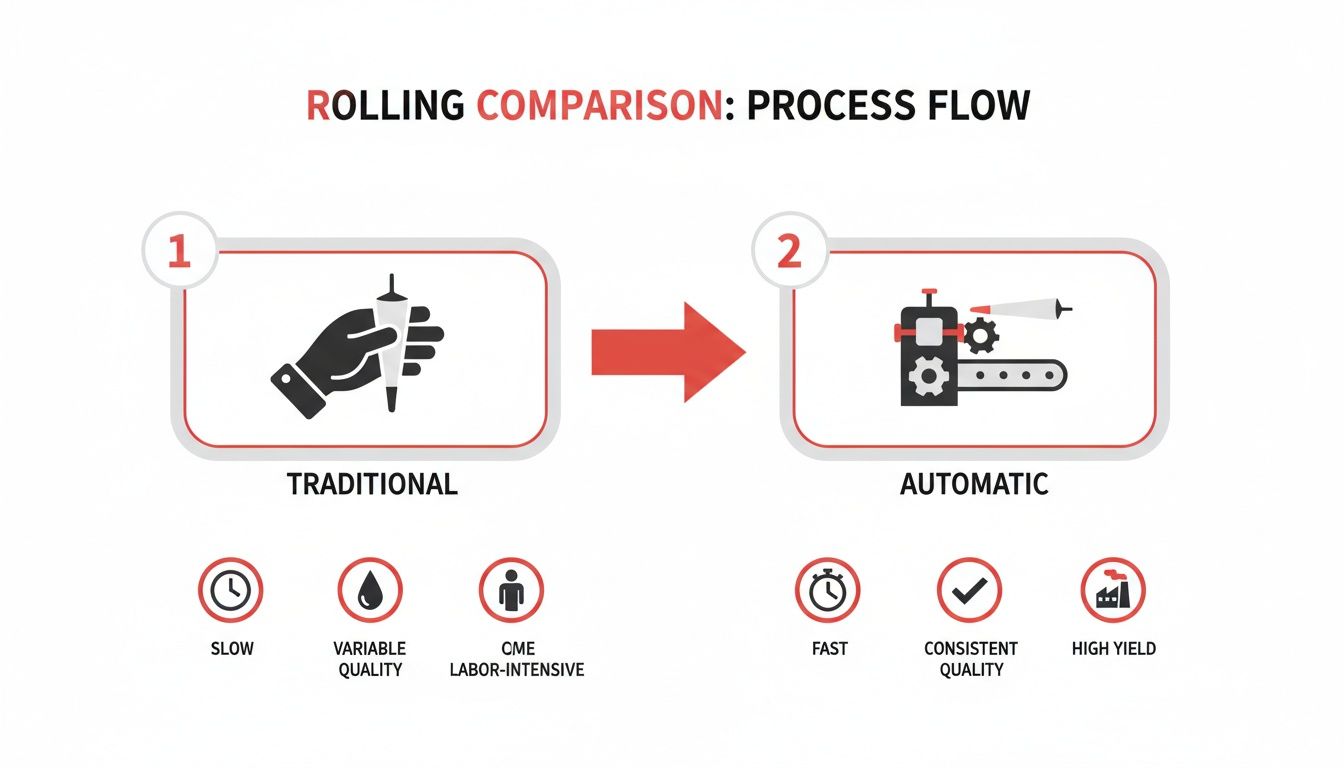

This comparison shows you just how different the manual and automated worlds are.

As you can see, automation swaps out inconsistent human skill for a high-yield system that nails quality every time.

Stage One: Grinding and Loading

It all starts with well-prepped flower. The machine doesn’t actually grind the cannabis, but the quality of your grind is everything. A consistent, medium-coarse grind is the sweet spot—it allows for great airflow and keeps the machine’s inner workings from getting gummed up.

Once it's ground, you load the flower into a hopper or chamber. This part is designed to hold a specific amount of material, which is the first checkpoint for making sure every joint has the same dose. Fancier machines even have sensors that monitor the fill level, so they can run continuously without missing a beat.

Stage Two: Filling and Compaction

This is where the magic happens. Instead of using your fingers to stuff a cone, an automatic roller takes a far more sophisticated approach. The two most common methods you’ll see are vibration and radial compaction.

- Vibrational Filling: Most machines, from consumer models to commercial workhorses, use tiny, controlled vibrations. These vibrations gently settle the ground flower into an empty cone, packing it evenly without making it too dense to smoke.

- Radial Compaction: Top-tier industrial machines, like the RollPros Blackbird, use patented tech that truly mimics a hand-roll. It wraps the paper around the flower and compacts it from all sides, creating a firm, straight joint instead of just a stuffed cone.

Getting this stage right is critical for a good smoke. A perfectly even pack is what prevents annoying issues like "canoeing" (when one side burns faster than the other) and ensures a smooth, slow burn from start to finish.

A key engineering goal in these machines is hitting a consistent pack density. This ensures that a 0.5-gram pre-roll feels and smokes exactly like every other one that comes off the line.

Stage Three: Sealing and Finishing

Once the joint is filled and packed, it’s time to seal the deal. For cone-filling systems, the machine tamps down the top and gives the excess paper a neat twist. This not only stops any flower from spilling out but also gives the final product that clean, professional look.

For machines that roll from scratch using big rolls of paper, the process is a bit different. The device applies a super-thin, precise line of moisture to the gum line right before it finishes rolling, creating a perfect seal. Some systems even use a touch of heat to set the seal instantly, making the joints ready for packaging right away. Finally, the finished joint is pushed out into a collection bin, ready to go.

The Commercial Advantage for Brands and Retailers

For cannabis brands, moving from hand-rolling to an automatic joint roller machine isn't just an upgrade—it's a total business overhaul. While a personal user gets convenience, a commercial operation unlocks a trifecta of game-changing benefits: massive scale, perfect consistency, and serious cost savings. This is the engine that lets a brand meet huge wholesale demand without ever compromising quality.

Think about it. How could you possibly supply a statewide dispensary chain with prerolls made one by one? The labor costs would be insane, and keeping every single joint at the same weight, density, and finish would be a logistical nightmare. Automation just wipes those problems off the board.

Driving Scalability and Consistency

The biggest win here is sheer volume. A single industrial-grade machine can crank out thousands of prerolls an hour—a job that would take a whole team of skilled hands to even attempt. This lets brands scale up production fast to fill massive purchase orders and keep the supply chain flowing.

Just as important is the consistency. Every single preroll that rolls off the line is a perfect twin of the one before it, with the exact same weight, pack, and airflow. That kind of uniformity is everything for building a brand that customers trust. People expect the same premium experience every time, and automation is the only way to deliver that promise at scale. You can also explore our guide on what are THCA pre rolls to see what goes into these popular products.

The global market for leaf rolling machines, which includes these automatic joint rollers, hit USD 6.6 billion and is expected to grow at a 6.8% CAGR through 2034. The automatic segment alone brought in USD 2.7 billion in revenue. That's a clear signal the industry is moving toward precision automation to cut human error and nail consistency—a must for any brand selling premium THCA products.

Achieving Significant Cost Reductions

That initial investment in a machine might seem steep, but the ROI shows up quickly through huge operational savings. The first and most obvious cut is in labor costs. Automating the rolling process dramatically shrinks the need for manual staff, freeing up your team for more important work like quality control and distribution.

Beyond payroll, these machines are incredibly efficient with materials. Their precise dosing systems make sure the perfect amount of flower goes into every preroll, which means less expensive plant matter spilled on the floor. In fact, some businesses have reported reducing product waste by up to 30%—a saving that goes straight to the bottom line.

- Labor Savings: Fewer employees needed for production means lower payroll expenses.

- Material Efficiency: No more spillage or overfills, so you get the most out of every batch.

- Reduced Training: Forget about the time and money spent training new rollers.

Unlocking New Market Opportunities

Finally, automation opens the door to new, high-margin product lines. The market for infused prerolls—joints kicked up a notch with kief, hash, or rosin—is exploding. Trying to make these consistently by hand is next to impossible.

An advanced machine can handle the complex layering and mixing needed for infused prerolls with total precision. This gives brands the power to innovate and grab a piece of that lucrative market. Plus, operating with this level of tech helps businesses meet Good Manufacturing Practices (GMP), a critical quality and safety standard that’s becoming a big deal in the regulated cannabis world.

How to Choose the Right Automatic Joint Roller

Picking the right automatic joint roller is a big deal. It’s like choosing between a daily driver and a commercial hauling truck—what works for a home setup won't cut it for a large-scale operation. The goal is to match the machine's power and features to your specific needs, budget, and how many prerolls you’re planning to crank out.

To narrow down your options, start by asking a few simple questions. How many prerolls do you realistically need to make in a day? Are you just working with flower, or do you want to get into blunts and infused products? And how much space do you actually have for this thing? The answers will guide you straight to the perfect machine.

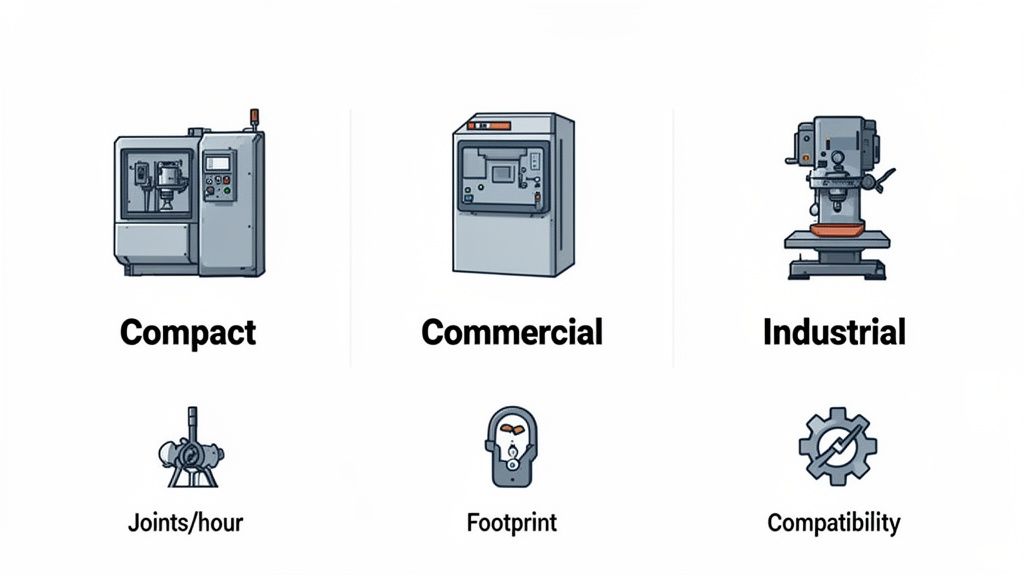

These machines fall into a few different tiers, from small-scale models perfect for craft brands to industrial giants built for mass production.

Here’s a quick breakdown to help you see where your needs might fit.

Comparing Automatic Joint Roller Machine Tiers

| Machine Tier | Typical Output (Prerolls/Hour) | Best For | Key Features | Estimated Price Range |

|---|---|---|---|---|

| Entry-Level | 100 - 400 | Personal use, small craft brands, R&D labs | Tabletop size, simple cone-filling, easy to operate | $2,000 - $10,000 |

| Mid-Range | 400 - 1,000 | Growing dispensaries, mid-sized producers | Higher capacity, better weight consistency, some material versatility | $10,000 - $50,000 |

| Industrial-Grade | 1,000 - 2,500+ | Large-scale producers, multi-state operators (MSOs) | Fully automated, true rolling capability, handles infused material, production line integration | $50,000 - $250,000+ |

Ultimately, choosing the right tier comes down to balancing your current output needs with your goals for the future.

Assessing Your Production Capacity Needs

The first and most important factor is production capacity—how many joints can it pump out per hour? For personal use or a small craft brand, a machine that produces a few hundred prerolls an hour is plenty. These are usually compact, easy to learn, and won't break the bank.

But if you're a licensed producer or a dispensary with high volume, the game changes. Commercial-grade machines can deliver anywhere from 500 to over 2,000 prerolls per hour. These are the workhorses of the industry, built to run all day and keep up with massive wholesale orders.

Automatic joint rollers are completely changing the game. Top-tier machines like the Hefestus AuraX can produce over 2,000 prerolls an hour, while the RollPros Blackbird clocks in around 900 hourly. This kind of automation can slash labor needs by 70-80% compared to hand-rolling. You can dig into more market data over at ResearchAndMarkets.com.

Material Compatibility and Versatility

Not every machine can handle every type of product. Before you pull the trigger, think about everything you want to make, both now and down the road. Some rollers are one-trick ponies designed only for standard flower-filled cones. Others are way more flexible.

Here’s what to keep in mind:

- Flower vs. Infused: Basic machines are great for ground flower. But if you want to make infused prerolls with sticky concentrates or kief, you'll need a machine built to handle that texture without clogging up.

- Cones vs. Straight Rolls: Most consumer-grade machines are actually just cone fillers. The high-end industrial systems can do true radial compaction, creating perfectly straight, cigarette-style rolls from a spool of paper.

- Blunts and Hemp Wraps: Blunt wraps are thick and delicate. You need a machine specifically designed to handle them without tearing. If blunts are in your product lineup, this is a non-negotiable feature.

Operational Footprint and Integration

It’s easy to forget, but the machine’s physical size—its operational footprint—is a huge deal. A compact tabletop model can fit in a small back room, but an industrial machine might be the size of a car and need its own dedicated floor space, special power hookups, and ventilation.

Beyond its size, think about how it fits into your workflow. Can one person run it, or does it need a team to load, operate, and collect the finished joints? The most advanced systems can even plug into a larger production line that handles weighing, packaging, and labeling. A smart decision balances the machine's output with the reality of your space and staff.

Mastering Your Machine for Flawless Results

Unboxing your new automatic joint roller machine is a great feeling, but that's just the start. To really get those perfect, consistent prerolls every single time, you need to master the entire process—from prepping your flower to dialing in the settings and keeping the machine clean.

Think of it like a high-performance espresso machine. You can't just throw any old beans in and expect a perfect shot. You need the right grind, the right temperature, and a clean machine. Your roller is no different. Ignore these details, and you'll end up with loose joints, jams, and prerolls that just don't smoke right.

Let's walk through a simple workflow to make sure every joint is as good as the last.

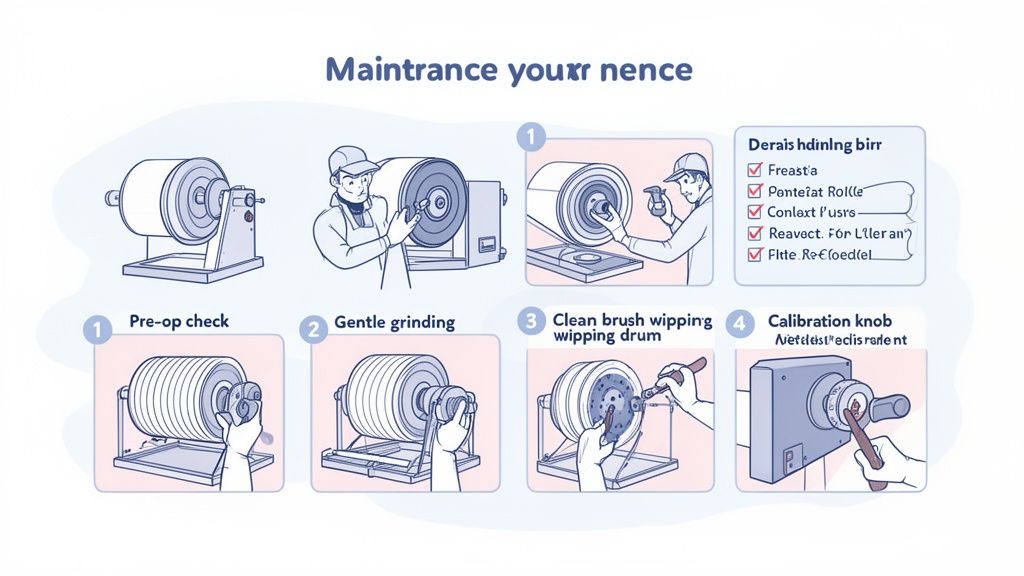

Pre-Operation Checks and Flower Preparation

Before you even hit the power button, a couple of quick checks will save you a world of frustration. Take a quick look inside the machine. Make sure the rolling chamber, hopper, and other moving parts are clean and free of any leftover flower or sticky resin from your last run.

Next up is your flower, and honestly, this is the most important part. The consistency of your grind has a huge impact on airflow, how evenly the joint burns, and how well the machine even works. Grind it too fine, and it’ll pack in way too tight, making it hard to draw and possibly clogging things up. On the other hand, a chunky grind leaves air pockets, causing the joint to burn unevenly and way too fast.

The sweet spot is a medium-coarse grind. You want it to look and feel uniform and fluffy, almost like crumbled oregano. This texture is perfect for letting the machine pack it evenly while still leaving room for great airflow.

Nailing the grind is a game-changer. If you want a deeper dive, our complete guide on how to grind flower has all the tips you need.

Dialing in the Perfect Settings

Most automatic joint rollers, especially the bigger commercial ones, let you customize your prerolls. These settings are your best friend for getting the exact density and size you're after, so don't be afraid to play around with them.

A good way to start is by running a small test batch. Keep an eye on these key adjustments:

- Density Control: This setting controls how tightly the flower gets packed. Start in the middle, check the finished joint's draw, and adjust from there. Too tight? Lower the density. Too loose? Crank it up a bit.

- Weight or Volume Calibration: If your machine doses the flower, make sure it’s calibrated to hit your target weight, whether that’s 0.5g, 0.75g, or a full gram.

- Cone Size Compatibility: Make sure your machine is set for the right size pre-made cones, like 84mm, 98mm, or 109mm king size. Using the wrong setting will lead to a messy fill or even damaged cones.

Once you find the settings that create your perfect preroll, write them down! This saves a ton of time and guesswork for future sessions and guarantees you get the same great quality every time.

Essential Cleaning and Maintenance

Want your machine to last and your prerolls to taste clean? You have to clean it regularly. Resin and tiny bits of flower build up over time, which can jam up the works and give your product a stale, burnt flavor. A simple cleaning routine is non-negotiable.

Here’s a quick checklist to keep your roller in top shape:

Daily (or After Each Session):

- Power Down: Always unplug the machine before you start cleaning. Safety first.

- Empty It Out: Get all the unused ground flower out of the hopper.

- Brush It Down: Use a soft-bristled brush to sweep out any loose particles from the main chamber and filling area.

- Wipe the Outside: A quick wipe with a dry microfiber cloth keeps it looking fresh.

Weekly (or After Heavy Use):

- Deep Clean with Isopropyl Alcohol: Grab a cloth or some cotton swabs and dampen them with 91%+ isopropyl alcohol. Carefully wipe down every part that touches cannabis to dissolve that stubborn resin.

- Check the Moving Parts: Look over any belts, gears, and rollers for buildup or signs of wear.

- Let It Air Dry Completely: Make sure everything is 100% dry before you put it back together. Alcohol evaporates fast, but any leftover moisture is bad news for your machine.

Staying Safe and Compliant

Running a high-performance automatic joint roller isn't just about making perfect prerolls. You also have to navigate the legal maze and keep your operation safe, whether you're a home user or a commercial producer. This gets even more important when you're working with popular hemp-derived cannabinoids like THCA.

The whole game with THCA flower comes down to one magic number: 0.3% Delta-9 THC. That’s the federal limit. To stay on the right side of the law, you absolutely must source your flower from suppliers who give you third-party lab reports, also known as Certificates of Analysis (COAs). Think of a COA as your product's passport—it proves what's inside is legal.

And remember, federal law is just the starting line. State laws can be wildly different. Just because THCA is legal on a federal level doesn’t mean your state agrees. It’s on you to know the rules where you live and anywhere you plan to ship.

Keeping Your Workspace Safe

Beyond the paperwork, let’s talk about physical safety. These machines are serious pieces of electrical equipment, and they need to be treated with respect. A little common sense goes a long way in preventing accidents and keeping your machine running for years.

Start with the basics. Always plug your machine into a grounded outlet—this is your first line of defense against power surges and shocks. If you have to use an extension cord, make sure it’s a heavy-duty one rated for the machine's power needs. Keeping your workspace clean and organized also does more than just boost efficiency; it prevents trips, falls, and other easily avoidable accidents.

Don’t forget about the air you breathe. Good ventilation is a must, especially if you're running the machine for hours at a time in a commercial setup. Proper airflow helps manage the scent and keeps the environment comfortable for everyone working.

Building Compliance Into Your Daily Grind

For any business, compliance isn't a one-and-done task. It has to be part of your daily routine. Your joint roller is just one tool in a regulated system, and building a compliant workflow ensures every preroll you produce is consistent, traceable, and safe.

Here's how to weave it into your process:

- Track Your Batches: Give every production run its own unique batch number. This number should connect the finished prerolls directly back to the THCA flower you used and its COA.

- Set Up Quality Control Points: Check your work as you go. This means regularly verifying preroll weights, looking for any visual flaws, and making sure your packaging is perfectly sealed.

- Test the Final Product: Once a batch is done, send a few samples of the finished prerolls to a third-party lab. This final check confirms your end product is still compliant and meets the quality standards your customers expect.

The boom in automatic joint rollers is part of a much bigger trend. The entire cannabis packaging equipment market is set to skyrocket from USD 1.9 billion to USD 8.9 billion by 2035. This massive growth is fueled by ongoing legalization and the need for high-volume, GMP-compliant production. You can dive deeper into how automation is changing the game at FutureMarketInsights.com.

Got Questions About Joint Rollers? We've Got Answers.

Thinking about grabbing an automatic joint roller? You probably have a few questions floating around. We get it. To help you figure out if one of these gadgets is right for you, we’ve put together answers to the most common questions we hear.

Think of this as your straight-to-the-point guide on everything from what kind of flower to use to how much upkeep is involved. Let’s clear things up so you can make a smart choice, whether you're a daily smoker or a business owner looking to streamline production.

Can I Use My Own THCA Flower in These Machines?

Absolutely. In fact, that's what they're made for. A good automatic roller is designed to work with all sorts of ground cannabis, including top-shelf THCA flower.

The secret to a perfect roll lies in the grind. You're aiming for a medium-coarse consistency—not too dusty, not too chunky. A super-fine grind can clog the machine, while big pieces will pack unevenly and burn poorly. Always give your machine's manual a quick look for any specific tips, but starting with well-cured, high-quality flower is always your best bet for a smooth, tasty joint.

How Much Maintenance Does an Automatic Roller Need?

A little bit of care goes a long way. To keep your machine running smoothly and your joints tasting clean, regular maintenance is a must.

After each session, just give it a quick wipe-down to get rid of any loose flower. For a deeper clean, use some isopropyl alcohol about once a week (or more, depending on how often you use it). This will prevent sticky resin from building up and jamming the works.

Pro Tip: Treat your roller like any other quality tool in your collection. A few minutes of preventative care each week will save you a ton of headaches down the road and keep your investment paying off with perfectly rolled joints every single time.

Is an Automatic Roller a Good Investment for Personal Use?

It really depends on your habits. If you only smoke once in a blue moon, a simple hand roller will probably do the trick.

But if you’re a true cannabis connoisseur who appreciates a flawless burn, smokes regularly, or loves sharing with friends, an automatic joint roller machine is a game-changer. It takes all the guesswork out of rolling, saving you a ton of time while delivering a perfectly packed joint that burns slow and even, every single time. If you value convenience and want to get the most out of your premium flower, the upfront cost is well worth the incredible experience.

And for those who love the craft of rolling and want to try something more advanced, check out our guide on how to roll a cross joint.

What Is the Difference Between a Roller and a Cone Filler?

Good question. People often use these terms interchangeably, but there's a slight technical difference.

A cone filler is usually a simpler device that uses vibration to pack ground flower into a pre-made cone. An automatic joint roller machine, on the other hand, is typically a more sophisticated system that can handle the entire process from filling and compacting to twisting the end shut.

Most of the devices you'll see on the market are technically cone fillers, but they automate the most annoying part of the process, giving you consistent, pro-level results without the hassle.

Ready to experience the ultimate in consistency and flavor? Explore the premium, California-grown THCA flower from Melt and discover how our commitment to quality can elevate your sessions. Every product is third-party tested and crafted for the perfect burn.